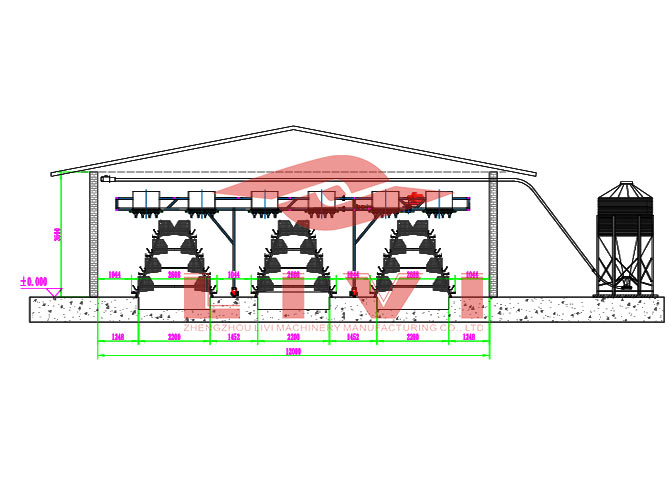

One Shed 2 Rows A-Type Layer Cage System for 5,000 Hens in Ghana

Project Overview

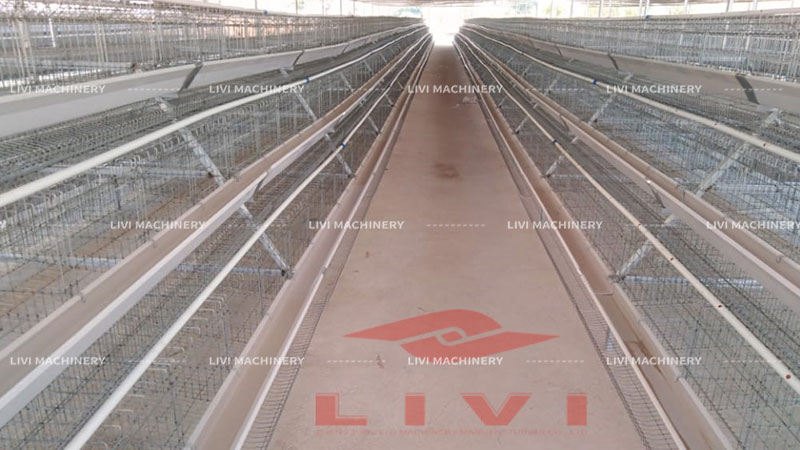

In April 2023, Livi Machinery supplied an A-type Layer Cage System to a small-scale poultry farm in Ghana, helping the customer establish a compact and efficient setup for over 5,000 laying hens. The project was designed to maximize use of space and improve farm hygiene through basic automation.

Project Details

This layer farm adopted a straightforward shed layout with manual operations supported by scraper manure removal to ensure daily cleanliness. Based on the site conditions and production scale, the following solution was implemented:

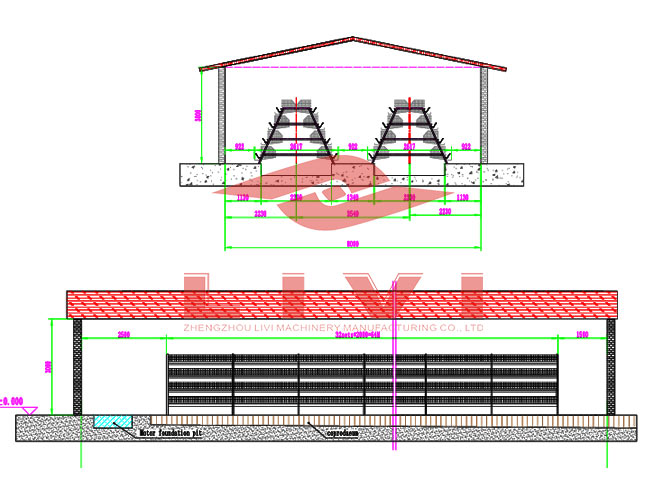

- Cage model: A-Type Layer Cages, 4-tier 5-door

- Cage size: 195 × 45 × 41 cm

- Chicken shed size: 36m × 8m × 3m

- Layout: 2 rows × 16 sets = 32 sets total

- Total capacity: 160 birds × 32 sets = 5,120 laying hens

This open-sided chicken shed supports natural ventilation, essential for local climate conditions and cost control.

Equipment Supplied

Livi provided a practical cage-based system with minimal automation:

- ✅ 32 sets of A-type Layer Cages (hot-dip galvanized)

- ✅ Nipple drinking system with water tanks

- ✅ Scraper-type manure cleaning system (1 set for 2 rows)

The scraper system reduces manual labor in manure removal while keeping the environment clean and odor-free.

Customer Feedback

The Ghanaian customer appreciated:

- The durability and anti-rust performance of the cages

- The simple yet effective scraper cleaning solution

- On-time shipping and easy installation

- Friendly and professional support from Livi’s technical team

Why Choose Livi’s A-type Layer Cage System?

Livi’s A-type Layer Cage System offers reliable and scalable solutions for small to medium egg farms. Whether for 5,000 or 50,000 birds, the system can be flexibly adapted to the local climate and available infrastructure.