Open Chicken House A-type Layer Cage System for 10,000 Laying Hens in Uganda

Project Overview

In May 2023, Livi Machinery delivered a complete A-type Layer Cage System to a poultry farm in Uganda, helping the client establish a productive open-sided chicken house designed to raise over 10,000 laying hens. The solution focused on structural simplicity, cage durability, and labor-saving manure management suitable for local farming conditions.

Project Details

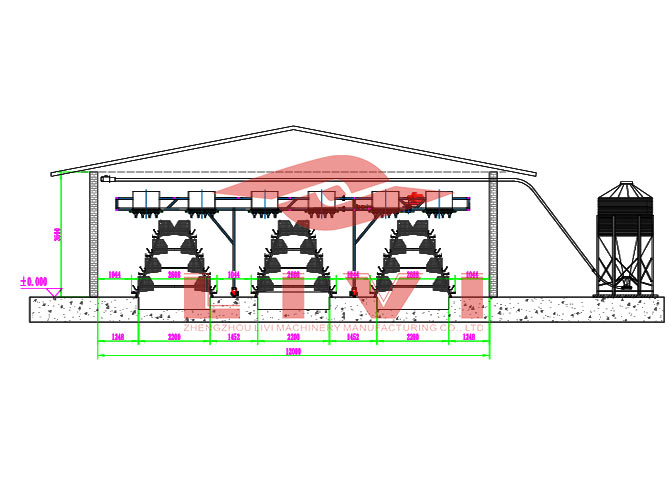

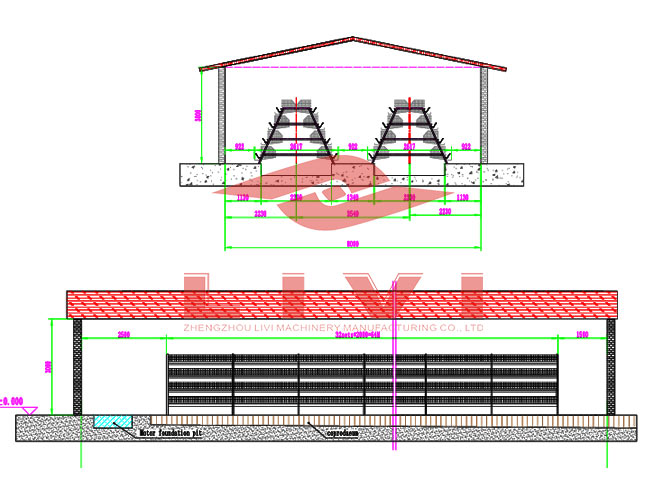

To meet the client’s goal of medium-scale egg production in an open environment, Livi designed a customized plan using 4-tier layer cages in a compact layout:

- Cage model: A-type 4-tier, 5-door

- Cage size: 1950mm × 450mm × 410mm

- Birds per cage set: 160 layers

- Chicken house size: 38m × 15m × 3.5m

- Layout: 4 rows × 16 sets = 64 cage sets

- Total capacity: 160 × 64 = 10,240 laying hens

The open-sided shed allows for natural airflow, reducing temperature buildup while keeping the birds comfortable in Uganda’s tropical climate.

Equipment Supplied

The farm was equipped with the following components:

- ✅ 64 sets of A-type Layer Cages (hot-dip galvanized, anti-corrosion)

- ✅ Nipple drinking system with water tanks

- ✅ Scraper-type manure cleaning system (2 sets for 4 rows)

This configuration combines basic automation and robust cage structure to create an efficient and low-maintenance egg production environment.

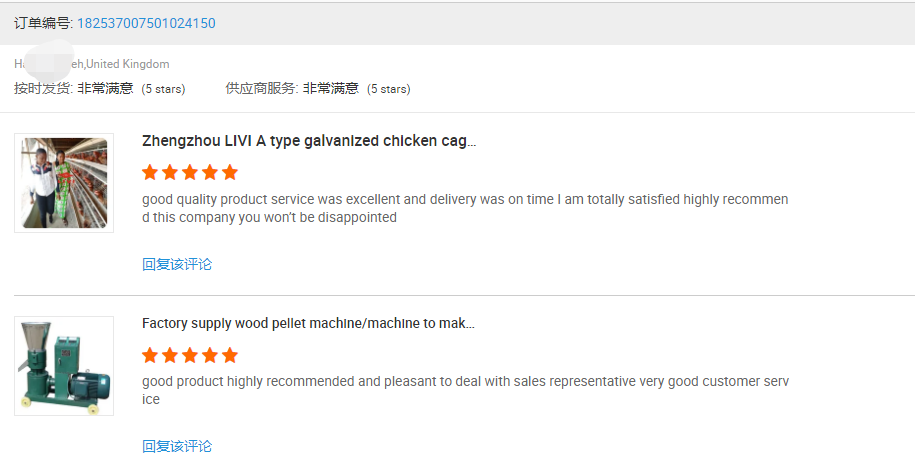

Customer Feedback

The Ugandan customer appreciated:

- The smooth and efficient scraper manure removal

- The strength and finish of the cage system

- Timely delivery and easy-to-follow installation instructions

- Livi’s prompt after-sales support and layout planning service

Why Choose Livi’s A-type Layer Cage System?

Livi’s A-type Layer Cage System offers:

- Reliable performance for tropical, open-shed operations

- Cost-effective manure cleaning via scraper system

- Durable hot-dip galvanized construction

- Optimized layout support for local farm conditions

This makes it an excellent choice for poultry farms in East Africa aiming to balance capacity and operational simplicity.