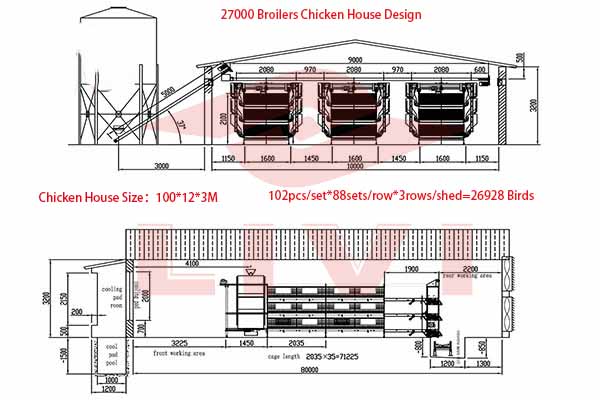

Optimizing Broiler Cage Systems for 300,000 Chickens in Nigeria

Broiler cage systems play a crucial role in the efficient and profitable operation of chicken farms. In Nigeria, where the poultry industry is rapidly growing, setting up a broiler cage system for 300,000 chickens requires careful planning and consideration of various factors. This article will explore the essential aspects to consider when designing a broiler cage system for such a large scale operation.

Key Considerations for Broiler Cage Systems

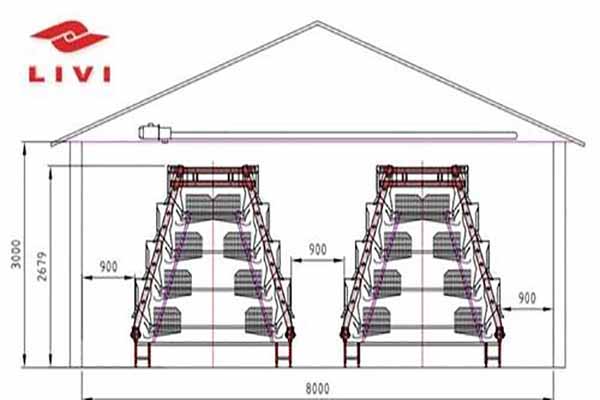

- Space Requirements

- Calculate the space required for each chicken to ensure comfortable living conditions.

- Typically, broilers need about 0.4 square meters of space per bird.

- For 300,000 chickens, you will need approximately 120,000 square meters of space.

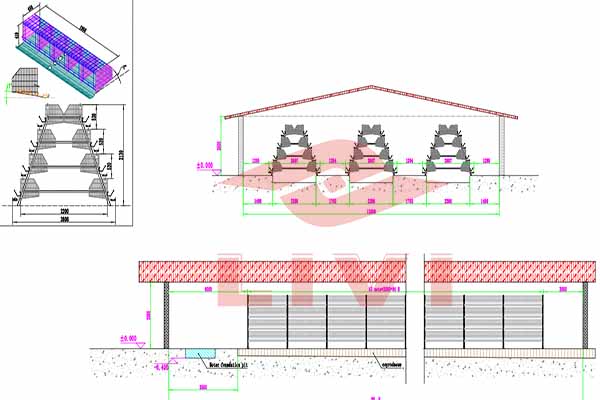

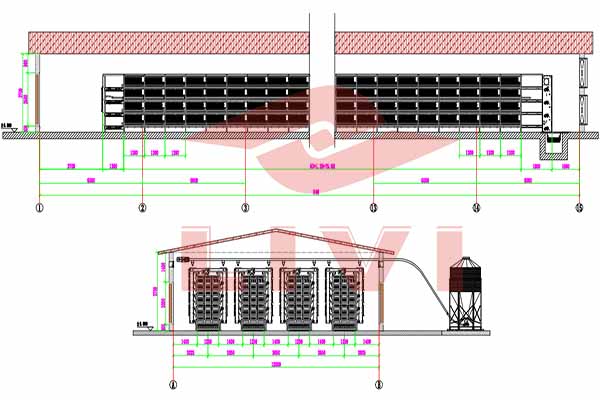

- Material and Construction

- Choose high-quality, durable materials for the construction of the broiler cages.

- Galvanized steel is a popular choice for its resistance to corrosion and longevity.

- Ensure that the design allows for easy cleaning and maintenance.

- Airflow and Ventilation

- Proper airflow is essential for maintaining optimal conditions for the chickens.

- Design the broiler cages with adequate ventilation to prevent heat stress and ammonia buildup.

- Consider incorporating fans and air exchanges to ensure a constant supply of fresh air.

- Feeding and Watering Systems

- Implement automated feeding and watering systems to ensure consistent access to food and water.

- Consider using nipple drinkers and automated feeders to minimize waste and improve efficiency.

- Health and Biosecurity

- Implement biosecurity measures to prevent the spread of diseases among the chickens.

- Regularly clean and disinfect the broiler cages to maintain a healthy environment.

Benefits of Investing in a Broiler Cage System for 300,000 Chickens

Investi ng in a well-designed broiler cage system for 300,000 chickens in Nigeria can yield several benefits:

ng in a well-designed broiler cage system for 300,000 chickens in Nigeria can yield several benefits:

- Increased Efficiency: Automated systems reduce labor costs and improve productivity.

- Improved Health: Proper ventilation and biosecurity measures help maintain a healthy flock.

- Reduced Waste: Automated feeding and watering systems minimize waste and improve resource utilization.

- Higher Profit Margins: Efficient operations lead to lower costs and higher returns on investment.

According to a report by the Nigeria Poultry Association, the poultry industry in Nigeria is expected to grow at a CAGR of 7.5% from 2020 to 2025. Investing in a state-of-the-art broiler cage system can help your farm stay competitive in this rapidly growing market.

Conclusion

Setting up a broiler cage system for 300,000 chickens in Nigeria requires careful planning and consideration of various fa ctors. By following the guidelines outlined in this article, you can create an efficient and profitable operation. For more information and a free chicken farm design and equipment quote, please leave a comment below or contact us at livi-machinery.com.

ctors. By following the guidelines outlined in this article, you can create an efficient and profitable operation. For more information and a free chicken farm design and equipment quote, please leave a comment below or contact us at livi-machinery.com.