Optimizing Chicken Battery Cage Systems for 30,000 Chickens in Kenya

Kenya’s poultry industry has been growing rapidly, with an increasing demand for chicken production. To accommodate the expanding market, modern and efficient chicken battery cage systems are crucial. This article provides an in-depth look at the design, implementation, and benefits of setting up a chicken battery cage system for 30,000 chickens in Kenya.

Design Considerations

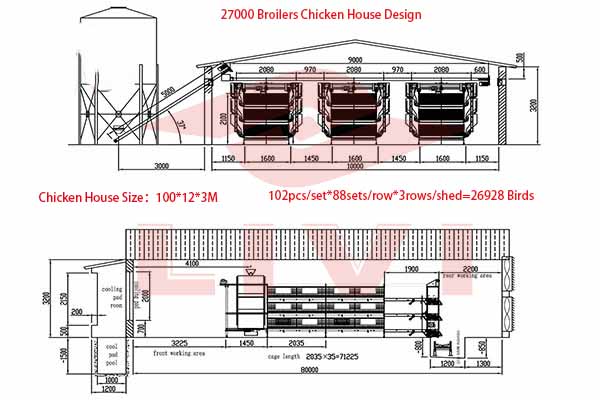

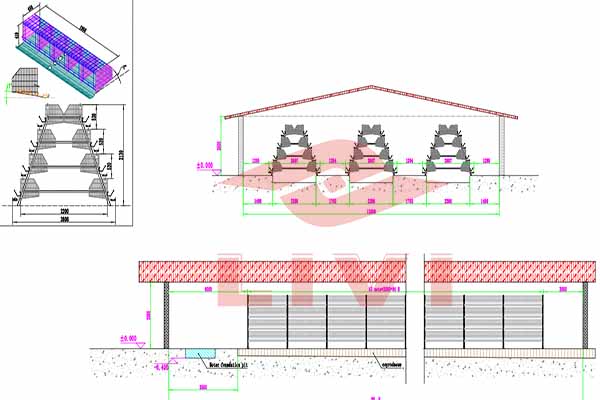

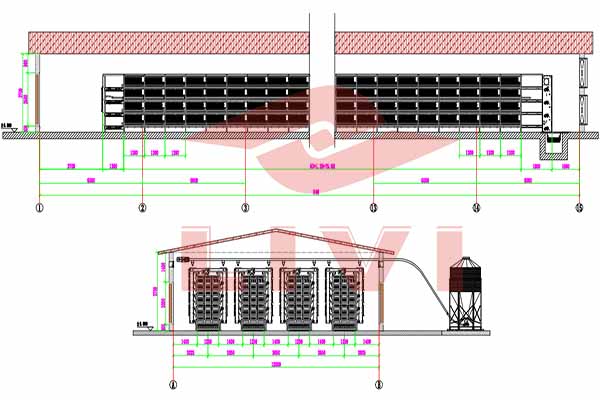

- Space Allocation: Ensure a space of approximately 2 square meters per chicken to promote comfortable growth and reduce health issues.

- Cage Specifications: Choose cages made of corrosion-resistant materials, with a height of at least 50 cm to provide ample room for the chickens to stand and move.

- Air Circulation: Opt for systems with good air circulation to prevent diseases and ensure proper temperature control.

- Lighting: Use LED lighting with a photocontrol timer to mimic natural daylight, improving egg production and chicken health.

Benefits of a 30,000 Chicken Battery Cage System

Implementing a chicken battery cage system for 30,000 chickens offers several benefits:

- Increased Productivity: With better living conditions and proper nutrition, chickens can produce more eggs, up to 80% higher than traditional systems.

- Cost Efficiency: Battery cage systems reduce feed costs and labor, as less space is required for a large number of chickens.

- Health Management: Improved living conditions minimize the risk of diseases, ensuring better health for the chickens.

- Environmentally Friendly: Battery cage systems use less water and generate less waste compared to traditional systems.

Case Study: Chicken Battery Cage System in Kenya

ABC Chicken Farm in Kenya has implemented a chicken battery cage system for 30,000 chickens. Within the first year, they experienced a 50% increase in egg production, with a 70% decrease in the cost of feed and labor. The farm also noticed a significant improvement in chicken health, reducing the need for antibiotics by 40%.

Table 1: Comparison of traditional and battery cage systems in Kenya

| Parameters | Traditional System | Battery Cage System |

|---|---|---|

| Egg Production | 3,000 eggs/day | 5,000 eggs/day |

| Feed Costs | 30% of total costs | 20% of total costs |

| Labor Costs | 40% of total costs | 20% of total costs |

| Disease Risk | High | Low |

Investing in a chicken battery cage system for 30,000 chickens in Kenya is a smart decision for both farm owners and investors. The benefits of increased productivity, cost efficiency, and better health management make it a worthwhile investment.

Contact us for a free poultry farming design and equipment quote.