Reliable Battery Cage for Chicken: 25,000-Layer Farm Project in South Africa with H-Type 4-Tier System

How a Compact and Automated Battery Cage System Boosts Layer Farming in South Africa

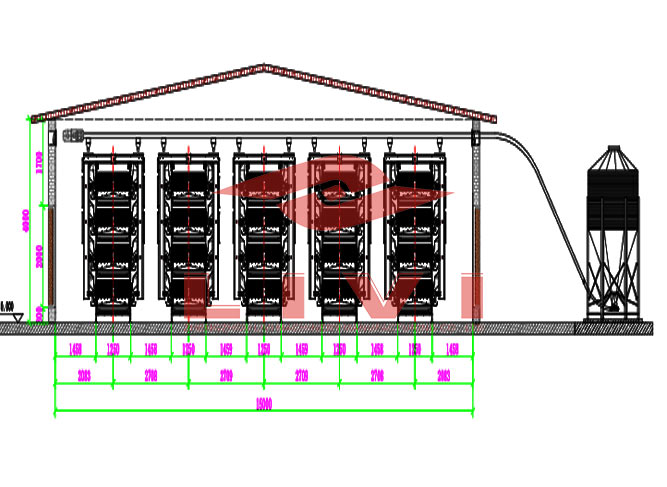

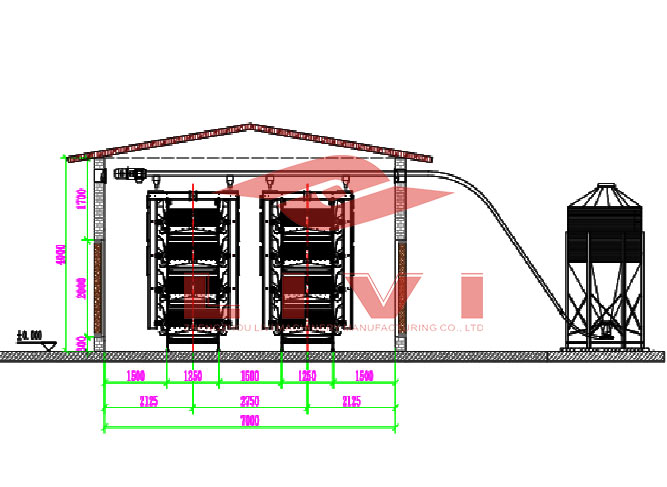

As egg demand continues to rise in South Africa, poultry farmers are turning to high-efficiency housing solutions that reduce costs while increasing production. One such example is this 2021 project in South Africa, where a commercial farm successfully raised 25,000 laying hens using an automated battery cage for chicken setup. The core of the project is a H-type 4-tier layer cage system, housed in a single, environmentally controlled poultry house with a 2-row layout.

With the use of modern chicken battery cages, the client solved issues related to land constraints, labor shortage, and climate variability—all while improving laying performance and operational control.

Project Overview

- Project Location: South Africa

- Flock Size: 25,000 laying hens

- System Used: H-type 4-tier battery cage for chicken

- Cage Layout: Single poultry house, 2 cage rows

- Cage Sets Installed: 174 sets

- Birds per Set: 144 birds

- Total Capacity: 25,056 birds

- Automation Level: Full Automatic – feeding, egg collection, manure removal, and drinking system

By installing 174 sets of H-type 4-tier cages, the farm now operates with more than 25,000 birds in a compact, easy-to-manage setup designed for long-term productivity.

Why Choose a Battery Cage for Chicken in South Africa?

Efficient Space Utilization with H-Type Layer Cages

The vertical 4-tier design allows high-density stocking while maintaining good airflow and accessibility. Even with just two rows in one house, the battery cage system achieves a total capacity of over 25,000 layers.

Climate-Resistant Design

South Africa has both dry and humid regions, and all cages are made of hot-dip galvanized steel, offering long-term resistance to rust and wear. The cage structure remains strong and reliable through seasonal changes.

Labor-Saving Full Automation

To reduce manual workload and improve productivity, the following equipment was included:

- 2 automatic feeding machine

- 2 automatic manure cleaning systems (1 per row)

- 2 automatic egg collection machines

- automatic drinking system with water pressure regulators

With automation in place, farm staff can manage daily operations more efficiently and focus on flock health and egg quality.

Equipment Supplied for 25,000-Layer Farm Project

| Equipment | Quantity | Description |

| H-type 4-Tier Chicken Cage Sets | 174 sets | 144 birds per set, total 25,056 birds |

| Automatic Feeding Machine | 2 sets | For automated feeding across the house |

| Automatic Manure Removal Systems | 2 sets | One for each cage row |

| Automatic Egg Collection Machines | 2 sets | One per row, belt-based collection |

| Automatic Drinking System | Full set | Water regulators connected to each row |

| Environmental Control System | Customized | Includes fans and wet curtains for stable airflow |

Client Feedback

“We needed a durable, efficient, and easy-to-operate layer cage system. LIVI’s battery cage for chicken setup gave us exactly that. The cages are sturdy, the automation is reliable, and we’re seeing better egg consistency with much less manual work. It’s a solid investment.”

— Poultry Farm Owner, South Africa

The client especially appreciated how the system performs under local conditions, with minimal maintenance required and fast adaptation for workers with little prior experience in large-scale poultry automation.

Benefits of Using Battery Cage System for Chicken Farming

- High layer density in a compact building

- Reduced labor cost through automation

- Corrosion-resistant materials for long lifespan

- Cleaner environment and lower mortality

- Scalable design for future farm expansion

- Year-round performance even in changing climates

Whether you are starting a new layer farm or upgrading an existing one, the battery cage for chicken from LIVI offers both performance and practicality.

About LIVI Machinery

LIVI Machinery has delivered professional poultry farming solutions to over 70 countries worldwide. Our layer cage systems, including H-type battery cages, are designed to meet the needs of modern farms through smart design, automation compatibility, and long-term durability.

📩 Email: [email protected]

📞 WhatsApp/WeChat: +86 155 3717 9350

🌐 Website: www.livimachinery.com